Exactly How to Pick the Perfect Industrial Coffee Mill for Your Service

Choosing the optimal commercial coffee mill for your business is a complex decision that needs mindful factor to consider of numerous crucial factors. It is vital to review your certain grinding demands, consisting of the quantity of coffee refined and the preferred grind consistency, as these components straight impact flavor and customer contentment. In addition, recognizing the different kinds of grinders offered can substantially affect your operational performance. As you navigate these considerations, one have to also evaluate the effects of budget plan and upkeep. What various other elements could make or damage your option?

Assess Your Grinding Demands

When choosing a commercial coffee mill, one must first examine their grinding demands to make certain optimum efficiency and uniformity. This first assessment involves recognizing the quantity of coffee to be processed daily, as well as the desired grind dimension for various brewing approaches. A high-capacity grinder might be necessary for organizations offering large amounts of coffee, while smaller sized procedures might locate an extra small version sufficient.

Moreover, it is necessary to take into consideration the sorts of coffee beans being made use of, as different beans may require specific grinding methods to accomplish the very best flavor profile. As an example, oily beans could demand a mill developed to deal with such characteristics without overheating or clumping.

Specialized coffee businesses often demand exact grind dimensions to enhance removal and taste, making it vital to choose a grinder that can supply consistent outcomes. Evaluating the available room and electrical needs will help in selecting a mill that fits flawlessly right into your operational workflow.

Understand Grinder Types

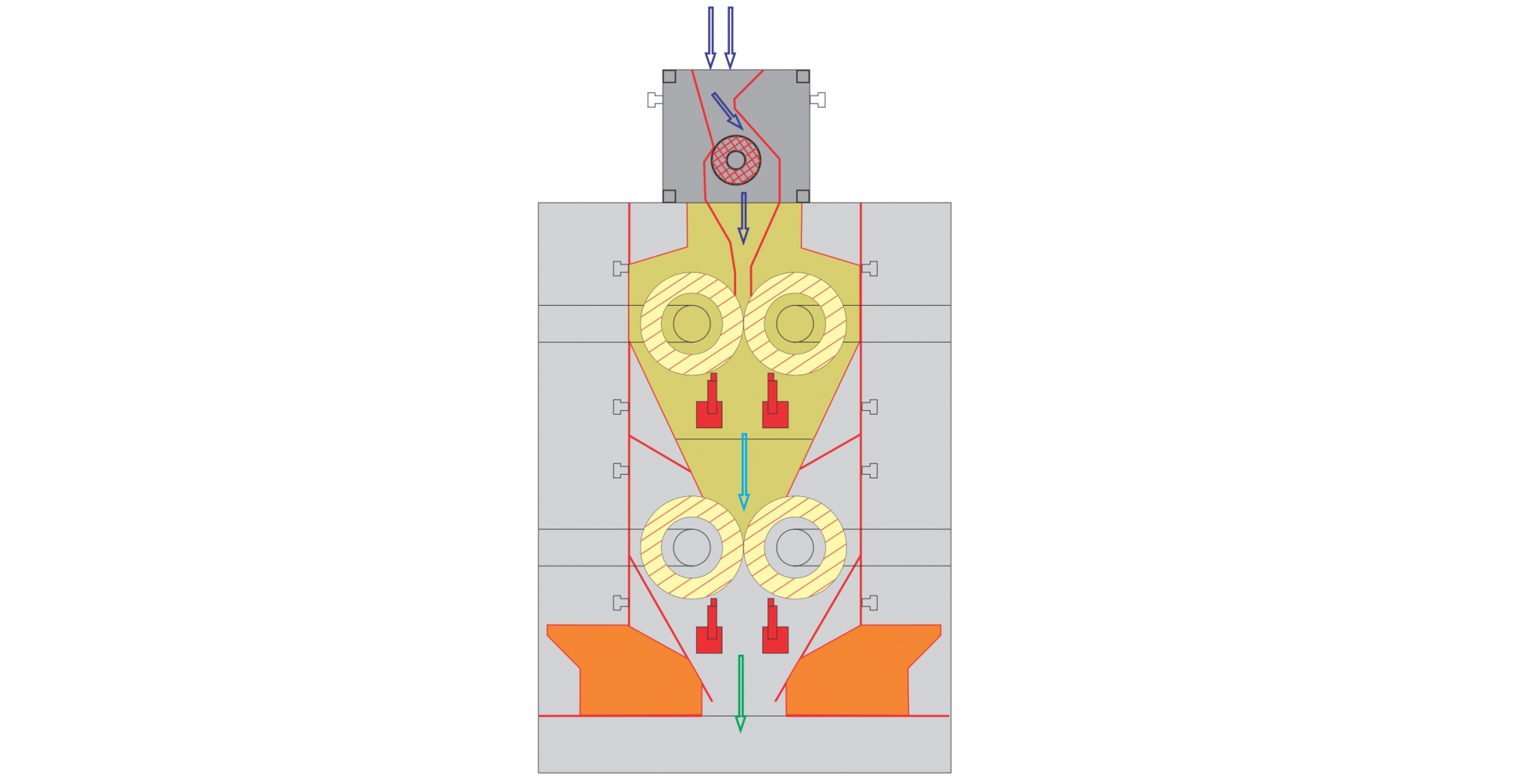

Understanding the numerous kinds of commercial coffee mills is crucial for making an educated selection that meets details operational demands. There are largely 2 groups of grinders: blade grinders and burr grinders.

Blade mills utilize spinning blades to cut the coffee beans, causing an inconsistent work dimension - Industrial Coffee Grinder. While they may be much more economical, they are frequently not ideal for business applications where accuracy is crucial

On the other hand, burr mills give a more consistent grind by crushing the beans between two surface areas. They can be additional classified right into level burr and cone-shaped burr mills. Flat burr mills supply a regular grind size and are normally preferred for coffee preparation, while cone-shaped burr grinders are flexible and can handle a series of brew methods, from espresso to French press.

When selecting a mill, consider the particular requirements of your service, including desired work uniformity, manufacturing quantity, and the kinds of coffee drinks you prepare to supply - Industrial Coffee Grinder. Each mill type has its limitations and benefits, so recognizing these nuances allows notified decision-making that aligns with functional goals

Evaluate Work Size Consistency

Attaining work dimension consistency is essential for producing top quality coffee, as variants in bit dimension can considerably affect removal and flavor. When selecting an industrial coffee grinder, it is critical to evaluate exactly how well the device keeps uniformity in grind dimension throughout different sets. Inconsistent grind sizes can result in irregular removal, causing a mug that might taste weak or excessively bitter.

To analyze grind dimension uniformity, consider mills with features such as flexible work setups and top quality burrs. Burr grinders, in specific, stand out in creating consistent bit sizes compared to blade grinders. The material and shape of the burrs play an important role, with stainless steel and ceramic choices offering toughness and precision.

Consider Production Ability

In the busy world of coffee manufacturing, considering production capability is vital for businesses aiming to satisfy demand without giving up high quality. The production capability of an industrial coffee grinder straight affects a company's ability to fulfill orders efficiently, manage supply, and reply to fluctuating market fads.

When analyzing manufacturing capacity, it is vital to review the mill's outcome rate, commonly gauged in pounds per hour. This dimension needs to align with your service's projected sales quantity and growth targets. A café with a high turn over may need a mill that can refine numerous hundred extra pounds daily, while a smaller YOURURL.com sized procedure may be sufficient with a reduced capability model.

In addition, think about the sort of coffee being refined. Different beans and blends might impact grinding rate and effectiveness, demanding a grinder with the ability of managing diverse manufacturing needs. It's likewise worth factoring in the mill's capacity to keep constant top quality under high outcome problems, as any type of variations can affect the last product.

Eventually, selecting a grinder that matches your organization's production ability will ensure you continue to be competitive and receptive to client assumptions.

Spending Plan and Upkeep Elements

When reviewing the best commercial coffee grinder, budget plan and upkeep aspects play a significant role in the overall decision-making process. An initial financial investment in a top notch mill can generate long-term benefits, however it's crucial to develop a clear spending plan that straightens with your organization's functional needs. Consider both the acquisition rate and potential operational prices, such best site as energy usage and substitute parts.

Industrial coffee grinders call for normal maintenance to make certain optimal performance and long life. Assess the producer's recommendations for upkeep, including cleansing routines and parts substitute, as these will impact long-lasting functional expenses.

Purchasing a mill that is durable yet easy to maintain can save money in time. While lower-priced alternatives may be alluring, they might incur greater maintenance costs and decreased performance. Eventually, stabilizing initial costs with long-lasting maintenance and operational performance will direct you to the ideal selection for your business's coffee grinding requirements.

Verdict

Picking the ideal industrial coffee mill requires an extensive evaluation of grinding needs, grinder types, grind dimension uniformity, manufacturing capability, and monetary factors to consider. By focusing on these aspects, businesses can ensure the purchase of a reputable, efficient grinder that satisfies certain functional demands. An appropriate mill not only improves the top quality of the coffee generated however likewise adds to the Get More Information total success and productivity of the business. Lasting performance and maintenance convenience ought to remain main to the decision-making procedure.

Specialized coffee organizations commonly demand exact work sizes to boost removal and taste, making it crucial to choose a mill that can supply uniform results. Flat burr grinders use a consistent work size and are commonly preferred for coffee preparation, while cone-shaped burr mills are functional and can manage a variety of brew approaches, from espresso to French press.

When selecting a commercial coffee grinder, it is important to evaluate just how well the maker maintains harmony in grind size throughout different sets. Burr grinders, in particular, stand out in producing consistent bit sizes contrasted to blade grinders.Picking the optimal industrial coffee mill necessitates a comprehensive evaluation of grinding demands, grinder kinds, grind dimension uniformity, production ability, and monetary factors to consider.

Comments on “A Beginner's Guide to Industrial Coffee Grinder Models”